SUSTAINABILITY

Hanwha TotalEnergies Petrochemical continues to promote management innovation activities in

order to become the world's No. 1 petrochemical company in terms of safety, cost and quality.

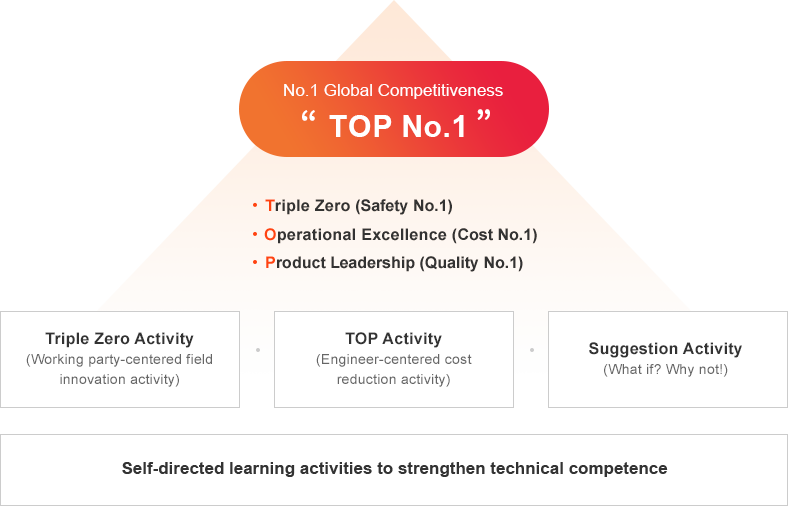

VISON

In order to become No. 1 petrochemical company with global competitiveness in terms of safety, cost and quality,

Hanwha TotalEnergies Petrochemical is engaged in constant management innovation activities: Triple Zero,

a working party-centered field innovation activity; TOP activities, an engineer-centered cost reduction activity; a suggestion activity,

a communication activity where all employees participate; and a self-directed learning activity for strengthening technological capabilities.

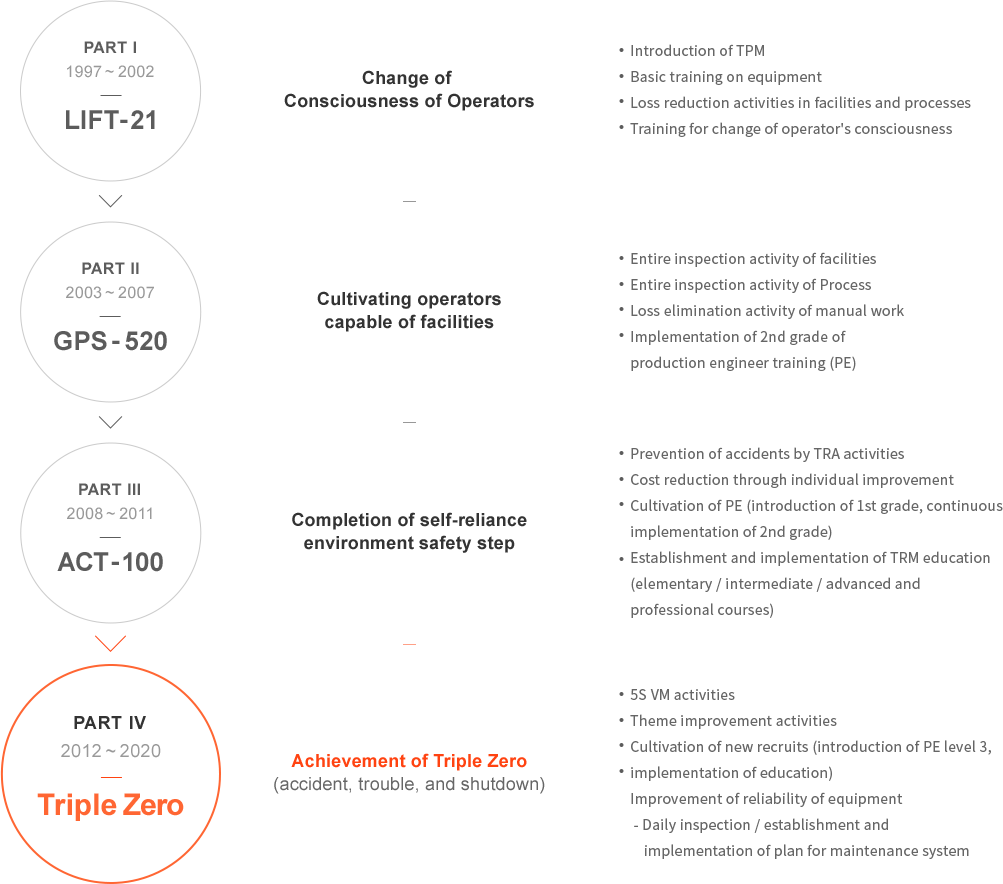

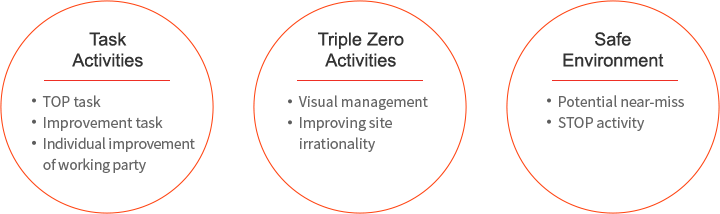

Triple Zero Activity

Hanwha TotalEnergies Petrochemical has promoted the working party-centered field innovation activity since 1997, aiming at

'Zero accident and stable · safe Plant'. Hanwha TotalEnergies Petrochemical carried out Part 1 focused on the ‘Self-reliance Preservation activity’,

Part 2 focused on the entire process and equipment examination and PE(Production engineering) training, and

Part 3 with the goal of achieving Accident Zero, Cost down 10 billion, and Plant Trouble Zero, and has proceeded with

Part 4 with the slogan of Triple Zero since 2012. Triple Zero, which started in 2012, is the ideal dream of all Plant which means Zero of shutdown,

trouble and accident. Hanwha TotalEnergies Petrochemical will try to achieve the Dream plant by 2020.

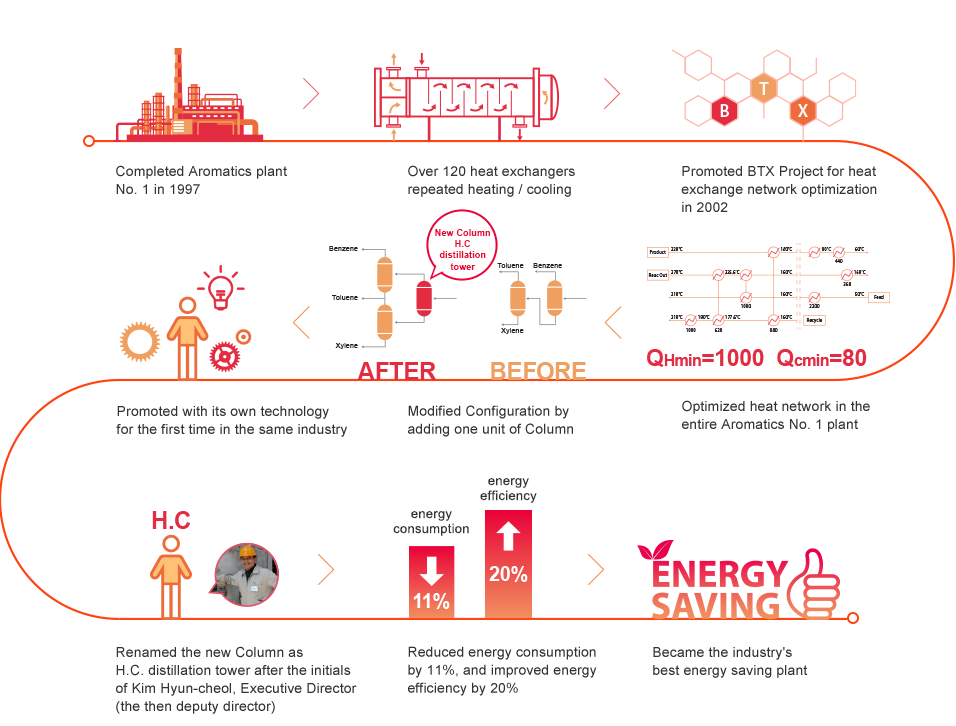

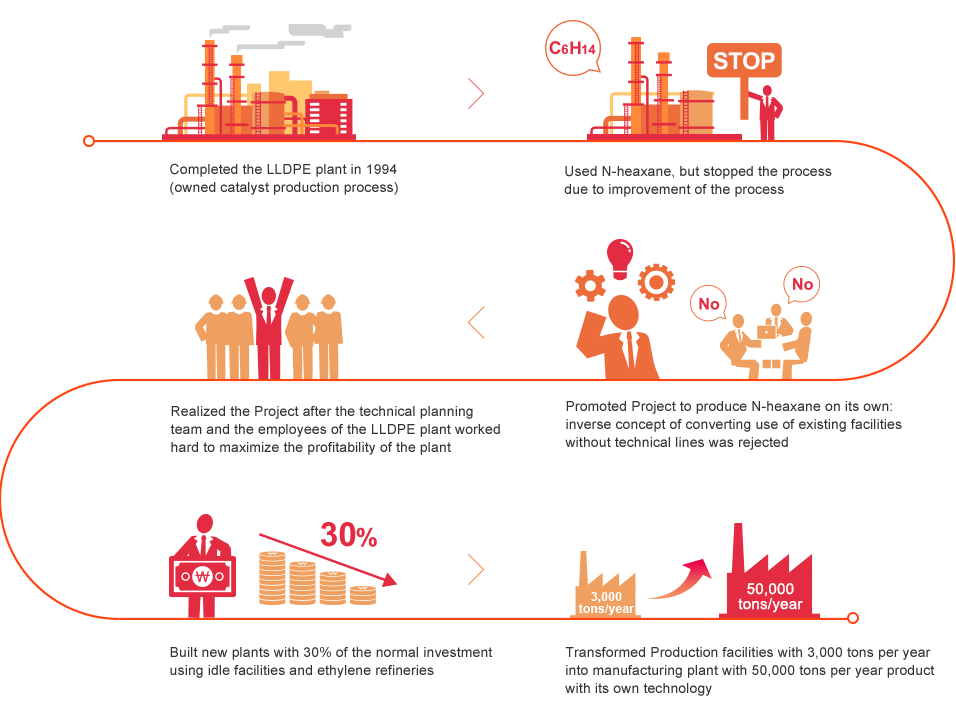

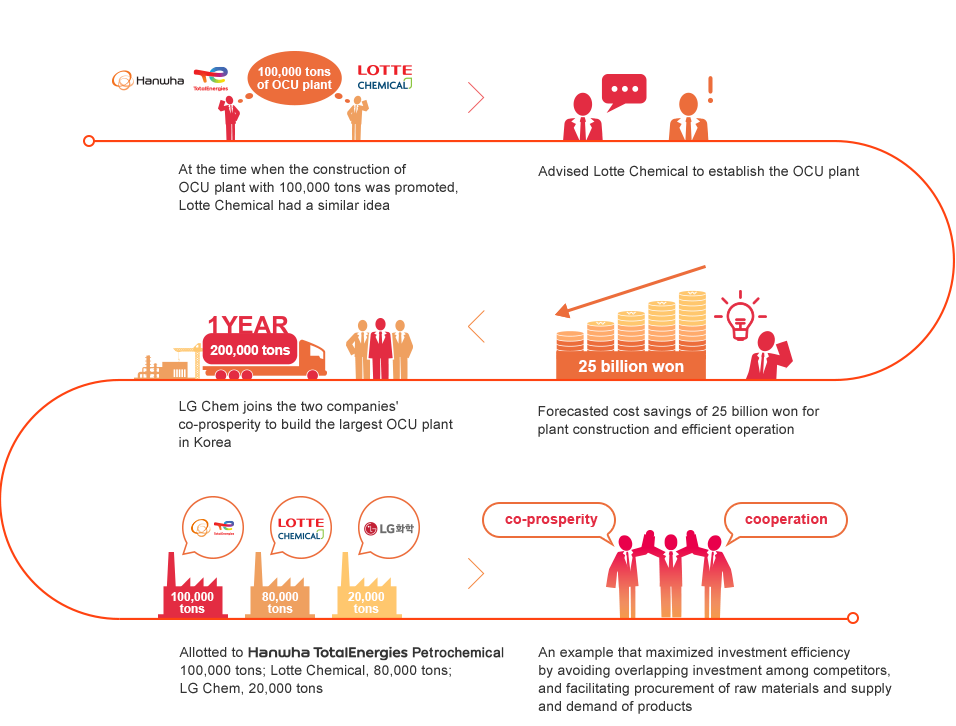

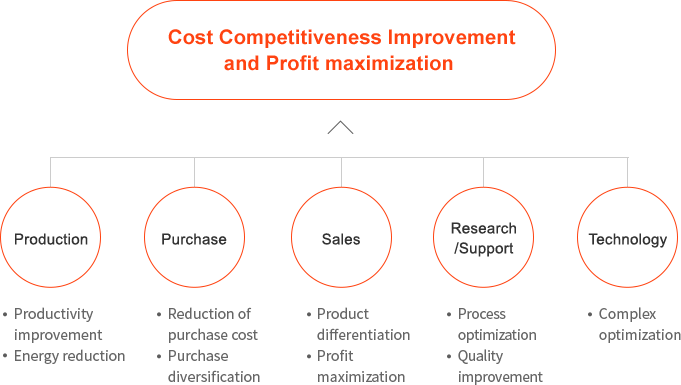

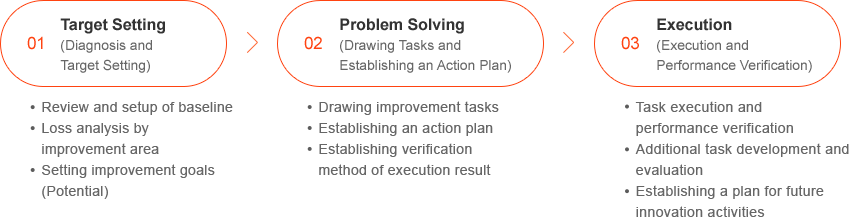

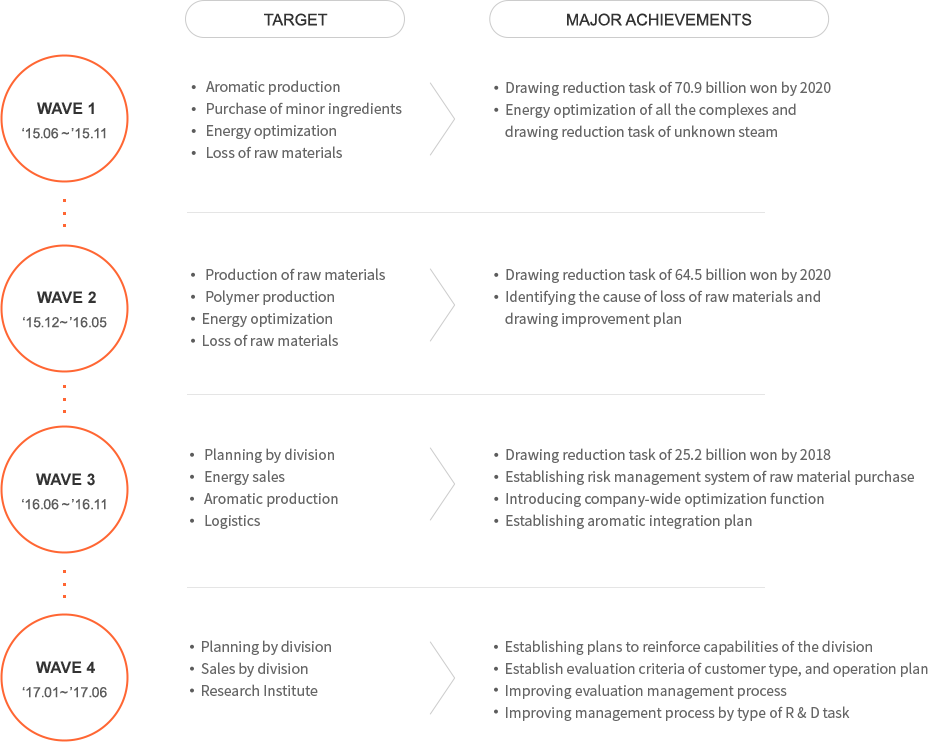

TOP Activity

An abbreviation of Total Operational Performance, TOP activity, developed by McKinsey in 1975 and applied to 2,500 companies around

the world, is management innovation program that maximizes profits through corporate-wide / overall operational efficiency activities.

Hanwha TotalEnergies Petrochemical proceeds with TOP activities annually as operational innovation activities to achieve Global Chemical

& Energy Leader, thus improving corporate performance in the short term and building a High Performing Culture.

What if? Why not!

Hanwha TotalEnergies Petrochemical is operating a suggestion system called ‘What if? Why not!’.

‘What if?’ means the progress of coming up with the creative idea based on the logical and liberal mind;

‘Why not!’ means developing the idea from ‘What if ?’ to the applicable specific one.

Hanwha TotalEnergies Petrochemical's suggestion activities are a means of communication where all employees participate,

contributing to innovating on the company, with approximately 120,000 cases submitted every year,

which the highest level of participation compared to other companies in the same field.

- Task Activities

- TOP task

- Improvement task

- Individual improvement of working party

- Triple Zero Activities

- Visual management

- Improving site irrationality

- Safe Environment

- Potential near-miss

- STOP activity

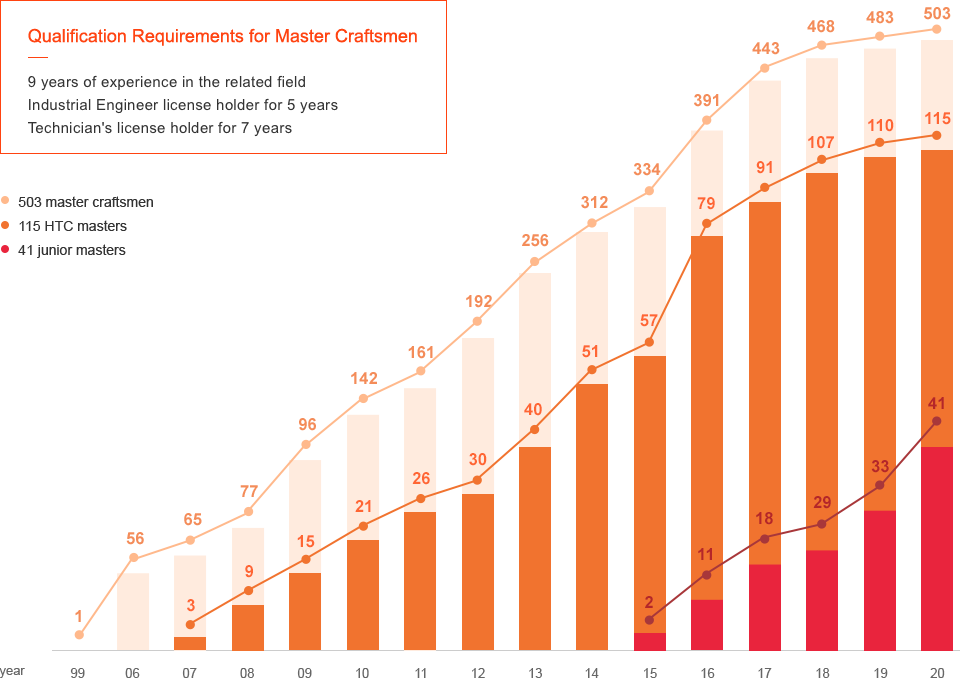

HTC Master

Hanwha TotalEnergies Petrochemical operates the HTC Master System, which is an in-house functional certification system, in order to treat technical

personnel considerately, and enhance the work performance of individual employees through employee self-development, thus leading to safe

operation of the plant. Since acquisition of the first master craftsman in 1999, Hanwha TotalEnergies Petrochemical has had 503 master craftsmen,

115 HTC masters, and 41 HTC junior masters, who are playing roles of top professionals in the company to improve the competence of junior

employees and ensure the safe operation of our plants. On the master street of the Daesan plant, you can see the faces and

names of proud masters engraved on the copper plate along with the beautiful nettle trees.

* Master Craftsman: Candidates should have 9 years of experience in the related field, industrial engineer license for 5 years, and technician's license for 7 years.

* HTC Master: Professionals of the related job who hold 2 mandatory master craftsmen and another master craftsman selected by taking into characteristics of the job or industrial engineer license

* HTC junior Master: Next generation professionals with more than three licenses higher than the Industrial Engineer license level which help the work, among employees engaged in the company for 10 years or less